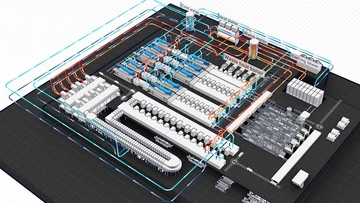

Maximum energy efficiency is one of the main objectives of product development at Dürr. One innovation that perfectly fulfills this requirement is the EcoQPower energy management system. It links all energy flows in the painting process so that excess heat and cold can be used elsewhere for heating or cooling.

In the CO2-free paint shop that Dürr recently built, EcoQPower uses software to control a combined heating and cooling network with heat pumps and water circuits. As a result, 21% less energy is required to operate the system. The second building block of the CO2-free paint shop is the use of electricity instead of fossil fuels. To this end, combustion technologies have been completely replaced by electrical alternatives. Since the customer uses green electricity, no CO2 emissions are incurred.

Dr. Jochen Weyrauch, CEO of Dürr AG: “Our formula is: Energy efficiency plus electrification plus green electricity equals CO2-free painting.” It sounds simple, but it’s not trivial: “At Dürr, highly specialized experts work every day on how to design the many individual processes in a paint shop in such a way that the end result is optimum efficiency and energy use.” The Group CEO considers the demand for sustainable painting technology to be high: “We are in the midst of a modernization cycle. Many paint shops are becoming outdated. When investing in replacements, customers are looking for both low energy consumption and maximum efficiency through automation.”

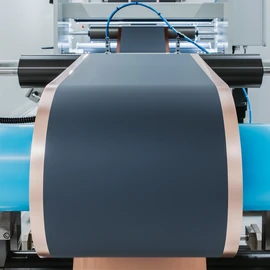

Major order in battery production technology

As part of its sustainable automation strategy, Dürr also sees itself as a partner for the efficient manufacture of low-emission products. These include, for example, electric cars and timber houses, but also battery cells for storing wind and solar power. In the business area of lithium-ion batteries, the company offers lines for coating electrode foils with anode and cathode material. Here, the Group reached an important milestone at the end of 2024, when it won its first major order for the delivery of several coating lines. “The project gives us the opportunity to demonstrate our competence also on a large scale, after having successfully implemented several smaller projects with battery manufacturers before,” says Dr. Jochen Weyrauch. The volume of the order placed by the Italian battery manufacturer FIB is in the high double-digit million-euro range. The start of production is scheduled for next year.

Balancing technology for fuel cells

The Dürr Group is also active in the field of environmentally friendly hydrogen technology. Group subsidiary Schenck Rotec, based in Darmstadt, supplies balancing technology for complete fuel cell units and components such as compressor wheels. Both have to be precisely balanced in order to keep vibrations as low as possible. Dr. Jochen Weyrauch: “As the global market leader in balancing technology, we are involved in future technologies such as the fuel cell at an early stage. Not only do we have a lot of specific experience, but we also invested early on in a modern Green Technology Center at Schenck in Darmstadt. This is where we offer optimal conditions for tests on the products of tomorrow.”

New climate strategy: 30% fewer emissions by 2035

The Dürr Group is also looking far ahead when it comes to reducing the greenhouse gas emissions attributable to it. At the beginning of 2025, the company adopted a new climate strategy for itself. It provides for a further 30% reduction in total emissions by 2035. This corresponds to a reduction in CO2 emissions of around 1.8 million tons to 4.2 million tons; the interim target for 2030 is 5.8 million tons. With these targets, the Dürr Group is in line with the Paris target of 1.5°C.

Dürr has already significantly reduced its emissions in previous years. In the period from 2019 to 2024, to which the previous climate strategy referred, greenhouse gas emissions decreased by 8%. The majority of the emissions attributed to the company — the so-called Scope 3 emissions — are generated during the operation of the machines and systems sold at the customers’ sites. By contrast, Scope 1 and 2 emissions arising within the company and from energy purchases are of secondary importance. Nevertheless, Dürr has done a lot to reduce them. For example, investments have been made in photovoltaic systems and the company has switched completely to green electricity. As a result, Scope 1 and 2 emissions fell by 55%, despite the acquisition of new companies and an increase in sales.

With the now targeted 30% reduction in total emissions by 2035, Scope 3 emissions are of paramount importance. These are also to be reduced by 30%. This presupposes, among other things, that customers will increasingly invest in new Dürr products with maximum energy efficiency and electric operation. The forecast also assumes an increasing share of green electricity in the electricity mix.