BBS Automation has been part of the Dürr Group since August 2023 and is the core of Production Automation Systems. With 16 locations in nine countries, the Garching-based company perfectly complements the Teamtechnik Group based in Freiberg/Neckar. Together they form one of the world’s leading suppliers of automated assembly and test systems for automotive components and plastic products. “Our goal was to create a high-performance center of competence for industrial automation,” explains Dr. Jochen Weyrauch, CEO of Dürr AG. “Today more than ever, automation is the key to efficient production: The quality and quantity requirements for many products are increasing to the point where manual processes are no longer an option. In addition, the shortage of skilled workers and the reshoring of production volumes to high-wage countries are increasing the demand for automated processes.” Against this backdrop, Dürr expects the market for the automation solutions it offers to grow by an average of 9% in the coming years.

Growth market e-mobility: opportunities with hairpin technology

The largest business area in automation technology is production lines for motors in electric cars. In the past, it was mainly automotive tier 1 suppliers who were engaged in their production. Now the car manufacturers themselves are increasingly getting involved, as they see the electric motor as a differentiating feature of their products. BBS Automation’s range for the e-mobility sector includes, for example, assembly systems for stators, rotors, inverters, and the motor itself. Teamtechnik offers test systems that can be used to test such components and the entire electric power train after assembly. And the Group subsidiary Schenck RoTec contributes balancing systems for electric motor components.

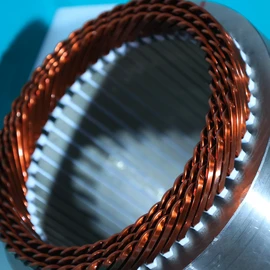

E-mobility is only just beginning to really take off. The pace of drive train development is correspondingly high. BBS Automation and Teamtechnik are keeping up with this pace. Take hairpin technology, for example: The wound copper rotor coils that generate the magnetic field in the electric motor are being replaced by innovative hairpin-shaped plug-in coils. The plug-in coils have a larger cross-section than conventional winding wires. This allows a higher current flow without overheating — an important requirement for more powerful electric motors.

BBS Automation has supported the development of hairpin technology with systems for production. The main objective was to replace the previous winding process with a technique for precisely pressing the hairpins into a three-dimensional shape. Hairpin technology is now used in most electric cars. The marketing potential for BBS Automation’s fully automated production technology is correspondingly high.

Powerful partner for major projects

Dürr’s newly established automation business also has good growth prospects outside the automotive industry. BBS Automation, for example, is strongly represented in the market with assembly lines for electric toothbrushes. Business with manufacturers of medical technology products also offers great potential. After all, the world’s population is growing and aging, while at the same time spending on medical care is increasing.

As a result, demand is growing for systems for the large-scale production of disposable medical products — from vaccination syringes and infusion sets to inhalers and nasal sprays. There is also an increasing demand for slimming injections. Such products can be manufactured by the millions on systems from BBS Automation and Teamtechnik — safely, with consistently high quality, and sterile if required.

Business with automotive and healthcare companies often involves large orders. In addition, suppliers of production technology are expected to be able to deliver worldwide. An international presence and a critical size are therefore an advantage. BBS Automation and Teamtechnik have both of these capabilities under the Dürr umbrella. “Our customers are often global corporations with high demands and an international production network. They welcome the fact that Teamtechnik and BBS Automation have joined forces in our group to form an efficient partner for the safe implementation of major investment projects,” says Dr. Jochen Weyrauch.