The Fraunhofer Institute for Building Physics IBP in Stuttgart has analyzed the effect of EcoQPower on the carbon footprint of paint shops. Two identical paint shop concepts were compared – one with and one without EcoQPower and each with all-electric operation using a conventional electricity mix. The result: EcoQPower reduces CO2 emissions by 19.2% over the entire life cycle of the paint shop, i.e. from production (including material transport) to recycling at the end of use.

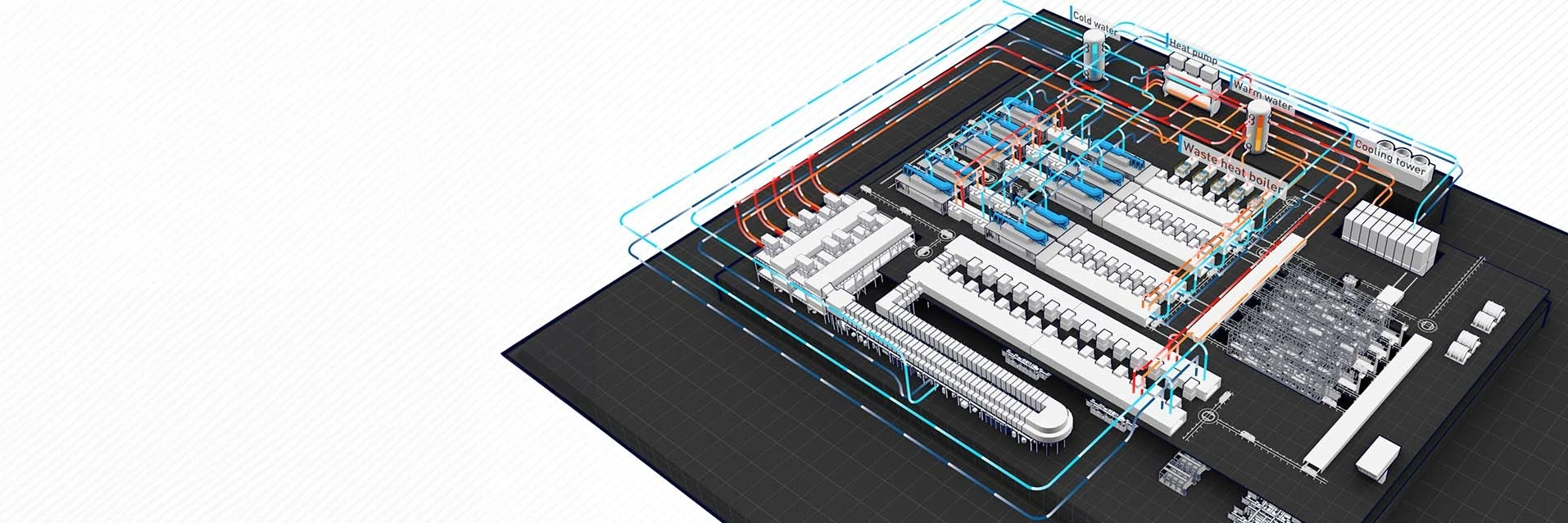

The utilization phase is particularly important: Thanks to EcoQPower, 21% less energy is needed in the painting process because the energy used is utilized much more efficiently. At the heart of the combined heating and cooling system realized with EcoQPower are heat pumps, water circuits, and intelligent software.

Dr. Jochen Weyrauch, CEO of Dürr AG: “Painting is the most energy-intensive value-added step in automotive production. Our innovation work is therefore focused on the development of sustainable and highly automated technologies with maximum energy efficiency. This is how we effectively support our customers in decarbonizing their plants and achieving their climate targets.”

The study of the Fraunhofer Institute shows: Energy-optimized operation of paint shops with EcoQPower improves not only the carbon footprint but also the economic efficiency. With a utilization period of 15 years and 110,000 painted cars per year, plant operators save costs in the seven-figure range yearly thanks to the 21% reduction in energy consumption.

The Dürr paint shop equipped with EcoQPower also meets the demanding EU Taxonomy requirements. The taxonomy is a central element of the Green Deal, with which the European Union wants to accelerate the climate-friendly restructuring of the economy. The regulations serve to classify sustainable investments that support climate and environmental protection.