The experience from the first project ensures synergy in the planning and execution of the new project. The use of largely identical project teams on both sides creates the best conditions for a smooth and efficient process. BBAC relies on the Integrated Paint Process (IP2) which has been tried and tested at Mercedes-Benz. This process eliminates the process stage primer application and the corresponding oven, reducing the complexity of the plant layout, as well as the energy consumption.

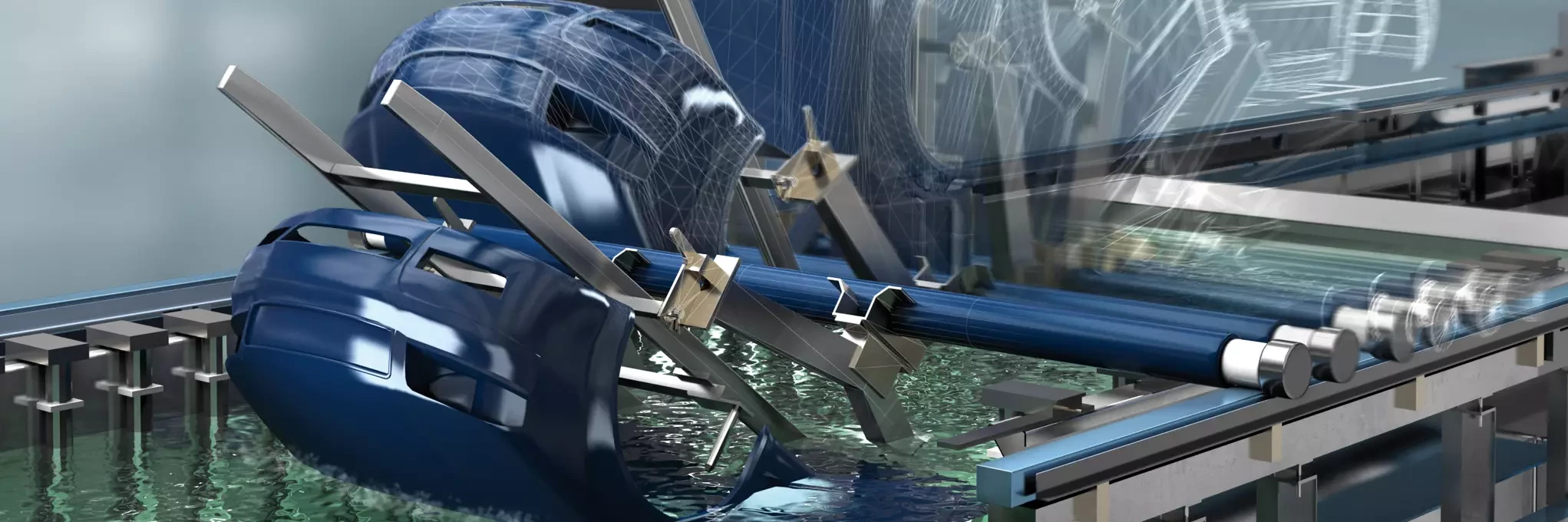

Starting at the PT/ED area, great importance is attached to sustainability. That is why the Ecopaint RoDip rotation dipping process is used, not only for pretreatment (PT) but also for electro dipping (ED). As the entire car body is rotated, there is no need for inclined sections at the entrance and exit to the dip tank. This not only saves a significant amount of floor space, but also consumes less energy and fewer chemicals due to the smaller volume of the tank. In this way, RoDip not only brings down unit costs, but simultaneously offers the best possible protection against corrosion by means of an optimized process of dipping, flooding and draining. Every year, more than 10 million car bodies worldwide are painted using the Dürr rotary dip coating process.

Following the pre-treatment, the seams on the bodies are sealed. At the same time, sealing robots spray liquid-applied sound deadening (LASD) onto the interior surfaces. A specially designed LASD nozzle is used for this purpose. Thanks to the automated process, this stage of production can be adapted very flexibly to the different car bodies passing through the plant. The time required for applying the sound deadening is also considerably less than was formerly required. Moreover, the bitumen mats that were previously applied were very sensitive to dust particles and were considerably heavier than the materials now applied. Sealing is carried out by 15 robots of the types EcoRS16 and EcoRS30 L16.

Next, in the spray booths, the base coat and clear coat are applied. A total of 60 robots of the types EcoRP L133, EcoRP L033, and EcoRP L030 paint the interior and exterior, also opening and closing the doors and hoods in a fully automated process. The painting technology that Dürr is installing in Beijing complies with stringent demands in terms of environmental impact. For example, the robots use the high rotation atomizers of the EcoBell2 generation to apply economical water-borne paints with low environmental impact to the bodies. Thanks to the flexible spray jet setting, different painting tasks can be mastered with the best quality and with a high degree of transfer efficiency.

In the interior painting zones, atomizer cleaning devices are used. These significantly reduce the number of manual cleaning operations otherwise necessary and help to guarantee the high production figures. Furthermore, the EcoPump9 gear dosing pump ensures minimal loss of paint and supports short color-changing times.

Binding of the overspray is performed by the energy-efficient EcoDryScrubber spray booth system. This dry separation of the overspray does without water or chemicals altogether, enabling the spray booth to be operated with 80% recirculated air. Thanks to this reduced expenditure on conditioning the air, the EcoDryScrubber saves up to 60% of the energy consumed by the spray booth.

The remaining solvent emissions from the spray booths and from the evaporation zones are reduced by around 90% by means of an exhaust purification system. The additional use of the dry separation (EcoDryScrubber) produces a highly concentrated and particularly efficiently filtered exhaust air. This enables a very compact air purification system to be used, comprising a high-efficiency VOC concentrator (Ecopure KPR) with downstream thermal air purification (Ecopure TAR). The energy of the desorption air that is necessary for the Ecopure KPR system is recovered from the pure gas of the thermal exhaust air purification system. This cuts investment costs for the exhaust system by 60%. In this combination, the energy demand for the exhaust air purification is reduced by 80%.

Energy-efficient technology from Dürr is even used in the ovens. The EcoC-IC (Convection with Integrated Conveyor) oven is characterized by the roller bed integrated in its base. With the sole exception of the drives mounted outside the oven cabin, all conveyor elements are installed below the floor panel to save space. This reduces the cross section of the oven and thus the thermal losses to the environment.

The exhaust from the ovens is purified by means of the Ecopure TAR integral afterburning system with heat recovery and is then reused for heating the oven. The exhaust air from the spray booths that is cleaned by the concentrator rotors is additionally ducted through a heat recovery system. This circulating system prewarms the intake air for the spray booths. It even enables a cooling effect to be achieved during hot summer weather.

With the Dürr Ecopure exhaust air purification, even the tougher higher emission limits that must be complied with in Beijing no later than 2017, are safely met. In this plant, which was ordered from Dürr in the third quarter of 2015, BBAC will paint 30 car bodies per hour.