Kirchentellinsfurt/Bietigheim-Bissingen, October 4, 2022 — Heading for the future at high speed: The Cellforce Group, a joint venture of sports car manufacturer Porsche and battery specialist CUSTOMCELLS, has successfully built up the mass production process for coating its electrodes over the past twelve months — relying on the knowledge, technology, and direct proximity to machinery and plant manufacturer Dürr. Today, the Cellforce Group and Dürr jointly commissioned a high-tech coating facility for high-performance battery cells in Bietigheim-Bissingen.

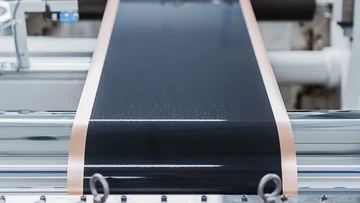

Specifically, the Cellforce Group (CFG) will soon be using a special process from Dürr that enables both sides of the electrode to be coated simultaneously. In this way, the coating process can be accelerated and the precision and quality significantly increased when compared to the standard procedure. In conventional processes, the anode and cathode materials are not applied simultaneously but rather one after the other on both sides of a thin metal foil.

In order to successfully commission and establish the process, the Cellforce Group has been on site at Dürr in Bietigheim-Bissingen for several months and has implemented production on a factory line. "For us, it was important that Dürr, as our technology partner, could act quickly and make possible adjustments directly. That's why we chose this Cellforce proprietary approach, which has greatly increased the speed of development of our coating process and allows us to build up shared knowledge at an early stage," says Markus Woland, Director Operations at the Cellforce Group.

Processes ready for a new Cellforce Group site

The technology for the double-sided electrode coating was developed by Dürr's US subsidiary Megtec, which was acquired in 2018. "We have a special technology that enables the Cellforce Group to manufacture top-quality high-performance cells — and to do so with a highly efficient and sustainable production process. By working directly with the Cellforce Group, we can optimally align the technology with their needs and thus support them in the future development and production of high-performance cells with high energy density," says Dr. Jochen Weyrauch, CEO of Dürr AG.

"Strong partnerships are needed for the development and production of future high-performance battery cells. The direct cooperation between the Cellforce Group and Dürr AG is a good example of how win-win situations can be created for all parties involved. This is a role model and thus sets standards for battery cell production in Germany," says Michael Steiner, Member of the Board of Management for Research and Development at Porsche AG.

The Cellforce Group is currently building a state-of-the-art development and production site for battery cells in the Reutlingen-Kirchentellinsfurt industrial park. Once this new site is completed, the production processes set up at Dürr can be taken over and continued directly. To ensure sustainable operation of the coating line, Dürr is also supplying equipment for exhaust air purification and the recovery of more than 99 percent of the solvents used.